Published on 20 September 2019

Vehicle lightweighting and optimization of assembly times are at the heart of current issues in the automotive industry. Decreasing vehicles' weight helps reduce pollutant emissions and extend range, while optimizing assemblies helps to control costs and to offer a variety of options to meet consumers' needs.

Today, affordable lightweighting of vehicles involves the use of multiple materials - steel, aluminum, plastics and composites - in the design of the vehicle and its body-in-white, in order to combine lightweight, strength and energy absorption and benefit from the characteristics of each material.

As a specialist in automotive fastening solutions, our expert teams have developed a range of flow-tapping screws to securely and durably assemble different materials (carbon-fibre composites, steel, aluminum, plastics, etc.): the EBS screw range. Our EBS flow-tapping screws allow assembling these various materials in a fast and reliable way, by robotic or manual assembly. They also allow the attachment of optional accessories and trim directly onto the body-in-white without a pre-punched hole.

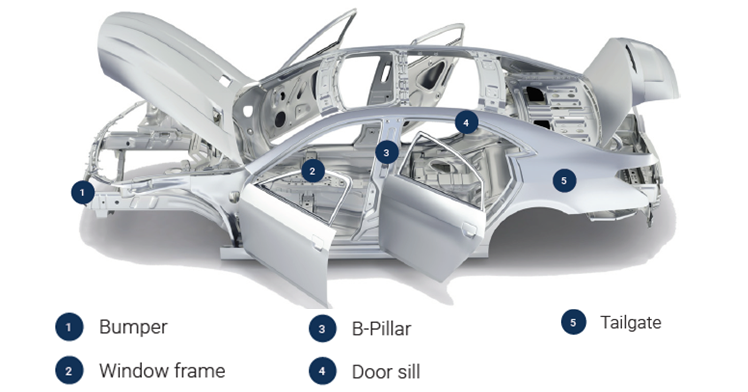

Our EBS screws can be used to facilitate the assembly of different elements of the bodywork (see illustration opposite), for example: the bumper, the window frame, the B-pillar, the door sill, the tailgate, etc.

100% ADDED VALUE

Beyond guaranteeing a durable and safe assembly, the EBS flow-tapping screw has advantageous technical characteristics, such as:

- Elimination of pre-drilling or pre-punching operations;

- Creation of a tapped barrel without residual shavings;

- Possibility to assemble additional components in different materials without pre-drilling;

- Low axial pressure required to install the screw thanks to its special geometry;

- Guaranteed fast screw mounting (± 1.6 seconds) for sheet metal thickness up to 7 mm for automated/2.5-3 mm for manual drilling depending on the material;

- Ability to remove the EBS screw and reuse the hole formed with a standard ISO screw, thus facilitating repair and recycling actions;

- Availability from M3.5 to M6, depending on the application.

100% INNOVATION

The EBS flow-tapping screw has been designed with a specific spiral placed at the end of the screw that creates additional heat to facilitate the flow-tapping of the sheet metal. The screw therefore needs less force to be put in place, thus avoiding any risk of material deformation.

The screw can be easily mounted in manual or automatic assembly, allowing adaptation to all your workstations. Therefore, the use of a robotic screwdriver is not essential for the installation of our EBS screw.

100% LISI

Thanks to the combination of our team's multidisciplinary knowledge, our EBS screw has been designed to answer your vehicle light-weighting and assembly optimization issues.

Our experience in fasteners and our expertise in the field of flow-tapping screws allow us to offer you the most effective solutions for each of your needs.

Discover our innovative fastening solution in the video below:

Let us transform together your challenges into successes

*Flow-tapping: cold working tapping technique.

Favorites

Favorites