PROCESS MASTERY

LISI AUTOMOTIVE produces over 5 million nuts and cage nuts each day. Every step in the manufacture of our parts is mastered in-house in order to guarantee our customers total quality. Our expertise covers all processes such as tooling, wire drawing, cold forging, tapping, and heat and surface treatments. This broad-based expertise is what sets our offer apart and allows us to propose innovative and reliable solutions to our customers.

HIGH-QUALITY PRODUCTS

Whether welded to the body-in-white or for securing the wheel hub, automotive nuts must have zero defects. Passenger safety and incident-free vehicle or module assembly can only be achieved if every single nut fits perfectly. Our expert engineering teams are able to develop the most appropriate threaded fastener solutions for all customer assembly challenges.

OUR EXPERTISE SUPPORTING YOUR INNOVATIONS

We offer a broad range of automotive-grade, standard and custom-engineered nuts to meet our customers’ most stringent requirements. Our experts study each request to ensure that our parts conform to the various changing environments. We undertake to offer a custom-engineered service for enhanced safety.

| Diameter: |

M2,5 to M20 |

| Materials: | Steel, high-temperature steel and high-strength steel, aluminum and stainless steel |

| Heat treatment: | Classes 4 to 12 |

| Threads: | Metric ISO, unified, special |

| Shape: | Hexagonal, square, rectangular, round, blind, duohexagonal, special |

| Drive geometry: | Hexagonal, duohexagonal or special |

| Base geometry: | With or without flange |

| Washers: | Optional free-rotating captive washers: flat, conical or serrated |

| Attachment/ Prepositioning: |

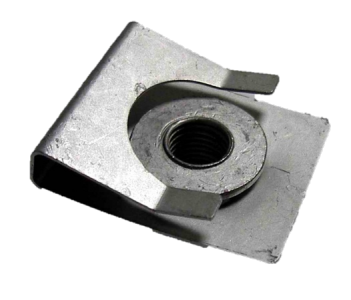

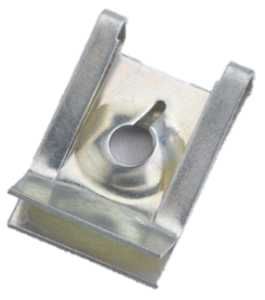

Weld nuts, self-piercing crimp nuts, metal/plastic cage nuts, stamped clipped nuts |

| Surface finishes: | Zinc phosphate, zinc flakes, zinc-nickel alloys or specials |

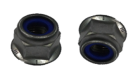

| Thread-locking & sealing: | Polyamide ring, slotted nut, deflected nut, top-coatings |

| Other: | Many special products & features |

Favorites

Favorites